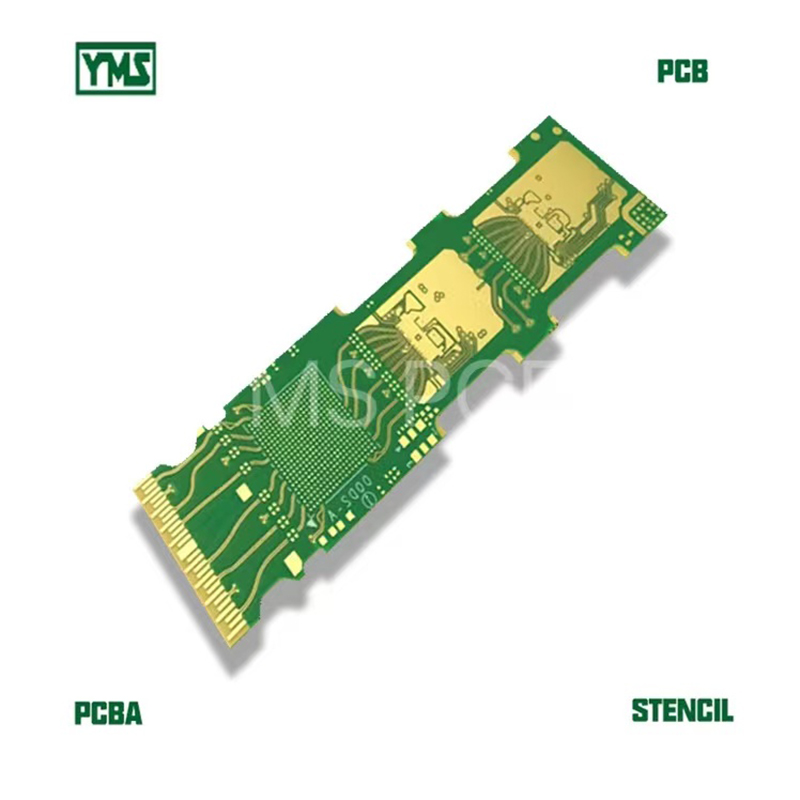

The hard gold edge connector multi-layer PCB produced by Mingzhenghong Electronics Co., Ltd. is made of FR-4 TG 140 material. The board thickness is 1.0mm±0.1mm, and the copper thickness of the outer and inner layers reaches 1OZ. The product size is 160mm x 100mm. Through precise impedance control technology, the stable transmission of electronic signals is ensured. The surface treatment process combines electroplated nickel gold (ENIG) and selective hard gold plating "50u" to provide long-lasting wear resistance for the edge connection part (gold finger) to adapt to high-frequency plugging and unplugging usage scenarios. The number of product layers is 8, the minimum drilling is 0.2mm, and the minimum line width/space is 0.13mm/0.15mm respectively. The combination of green/yellow/black matte solder mask ink and white/yellow silk screen color creates clear appearance identification. This PCB is suitable for automotive, intelligent communications, industrial control, LED, power supply, medical and other fields, and can adapt to high-speed, high-frequency circuit requirements. The company strictly follows international quality and environmental management system certification to ensure the professionalism and high reliability of its products.

1. Precision controlled resistance technology: Through fine impedance control, it ensures stable transmission of electronic signals and adapts to high-speed signal requirements. 2. High-end materials and technology: Using FR-4 TG 140 base material, combined with electroplated nickel gold and selective hard gold "50u" treatment to enhance plugging and unplugging durability. 3. Optimize design parameters: 1.0mm±0.1mm plate thickness, 1OZ inner and outer copper thickness, support minimum drilling of 0.2mm, and provide minimum line width/space of 0.13mm/0.15mm. 5. Environmental certification guarantee: Comply with ISO9001, ISO14001 certification, and comply with environmental standards such as RoHS and REACH to ensure the environmental friendliness of products.

1. Automotive electronics: Adapted to high-frequency plug-in and unplug environment, suitable for key electronic equipment such as automotive internal control systems, navigation, and multimedia. 2. Intelligent communication equipment: Meet the circuit board needs of high-speed communication products such as smartphones, base stations, and network equipment. 3. Industrial control system: It is suitable for application scenarios with high protection requirements such as industrial automation control devices and mechanical operation panels. 4. High-definition LED and power supply: Provide circuit bases for LED lighting, high-performance power modules, etc. to ensure long-term stable operation. 5. Medical equipment: serving precision medical instruments, monitoring equipment, etc., meeting the high standard requirements of the medical industry for circuit boards.