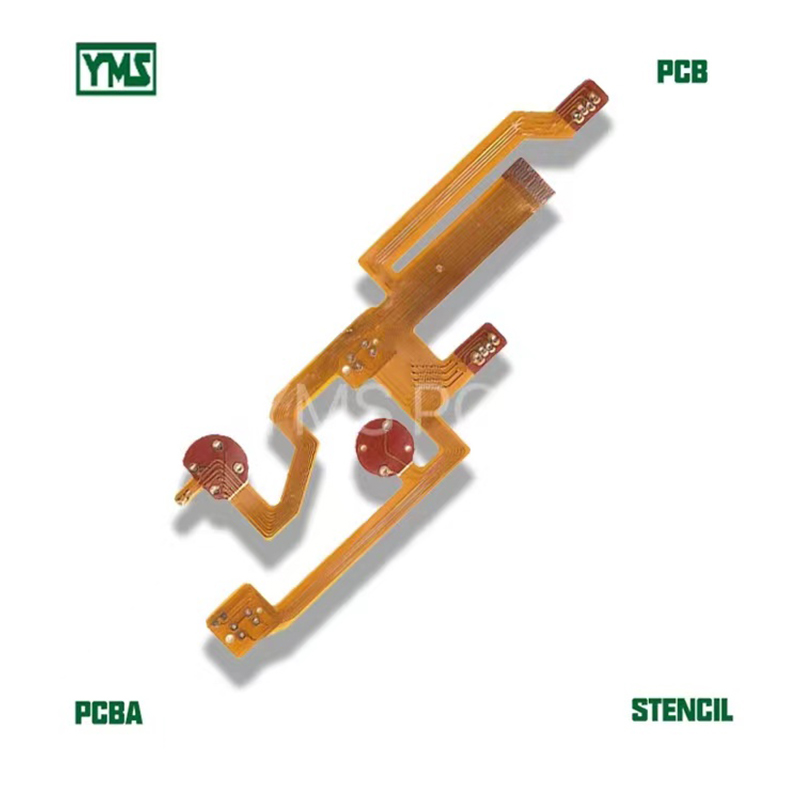

Flexible printed circuit board (FPC) is a circuit board made of polyimide (PI) as the substrate, with good bending and folding tolerance. Through the optical imaging transfer and etching process, the conductive copper line pattern is constructed, and the two-layer and multi-layer FPC is connected to the inner and outer layers through the metallization process of drilling. The external pattern is protected and isolated by PI material and yellow cover layer to ensure the safe operation of the circuit. Mingzhenghong Electronics Co., Ltd. produces single-sided, double-sided and multi-layer flexible printed circuit boards, and provides assembly services, including surface mount technology (SMT), plug-in (DIP) and functional testing, which can meet the needs of products such as electronic chargers, mobile phones, laptops, batteries, industrial control systems and embedded LED displays.

1. Superior flexibility: Using polyimide (PI) as the substrate, it provides excellent bending and folding performance, suitable for complex assembly and space-constrained design. 2. Precision circuit layout: With advanced manufacturing technology, it achieves a minimum line width/line spacing of 0.05mm/0.05mm (2mil/2mil) and a minimum aperture of 0.15mm (6mil), meeting the requirements of high-precision circuits. 3. High-quality surface treatment: Using ENIG (electroplated nickel/gold) surface treatment technology to ensure excellent welding performance and long-term circuit reliability. 4. Customized services: Provide customized options from single-sided to multi-layer boards, as well as integrated assembly services, including SMT, DIP and functional testing, to meet the personalized needs of different customers.

1. Portable electronic products: Suitable for smartphones, laptops and electronic wearable devices, supporting the needs of these products for thin and compact design. 2. Industrial and automotive applications: Can be widely used in industrial control systems, car navigation and sensors, etc., providing durable and reliable circuit solutions; 3. Medical equipment: Suitable for highly sensitive medical testing and monitoring equipment, meeting the medical industry's special needs for flexibility and precision. 4. High-end consumer electronics: Suitable for high-end consumer electronic products such as embedded LED displays and electronic chargers, ensuring the product's advanced nature and user experience.