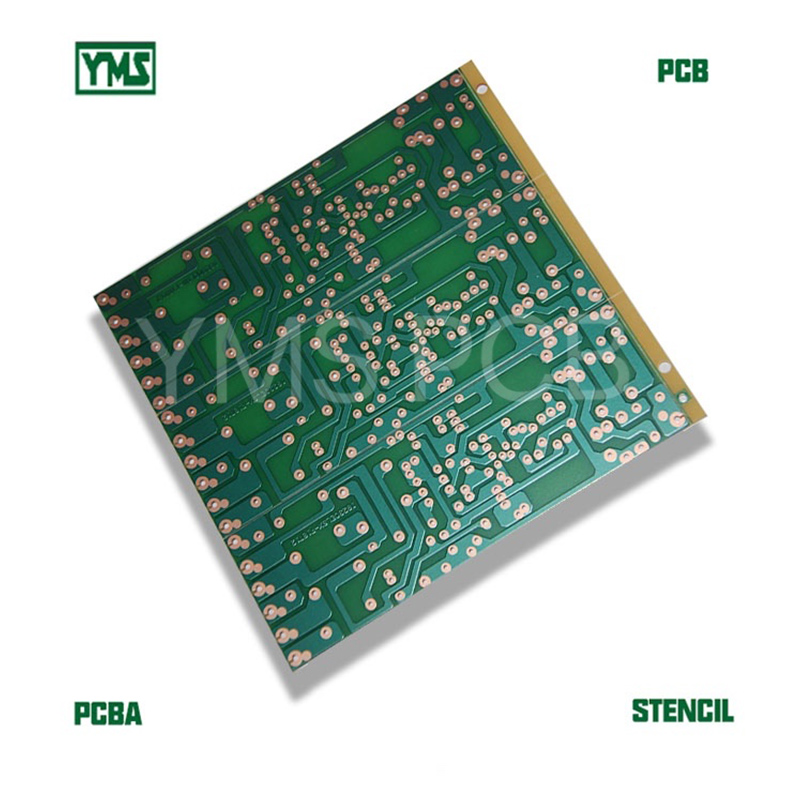

The 4-layer 4OZ copper thick impedance control circuit board produced by Mingzhenghong Electronics Co., Ltd. is a bare board PCB product specially customized for high-power electronic equipment. This product implements strict controls on etching and solder mask processes to meet the special requirements of power electronic equipment for heavy copper PCBs. We provide mature impedance control technology to ensure the signal integrity and stability of the circuit board. The products are used in core components of power electronic equipment, demonstrating professional capabilities in heavy copper PCB manufacturing and supporting mass production requirements up to 12 OZ copper thickness.

- High power adaptability: It adopts 4OZ heavy copper design and is evenly laid on the 4-layer board, which improves the current carrying capacity of the circuit board and adapts to the needs of high current and high power equipment. - Precise impedance control: Impedance control is achieved through mature technical means to ensure the stability and integrity of signal transmission and reduce signal loss. - Use of high-quality materials: TG170 highly flame-retardant FR-4 material is used to ensure the stability and durability of the PCB in high-temperature environments and increase product life. - Environmentally friendly production process: Coated with green solder mask ink and white screen printing, it complies with environmental standards, and the surface chemical gold plating (ENIG) treatment enhances weldability and oxidation resistance. - Precision dimensional processing: It meets the high-precision manufacturing requirements of a minimum aperture of 0.5mm and a minimum line width and line spacing of 0.3mm, adapting to precision electronic applications.

- Power electronics field: suitable for high-power switches, frequency converters, power amplifiers and other core components of power electronics that need to carry large currents. - Industrial automation system: It can meet the requirements for high-performance PCB in industrial automation control systems. Stability and durability are key considerations. - Communication and 5G equipment: Play a key role in signal transmission and processing, ensuring accurate signal transmission in communication equipment. - New energy and automotive electronics: Suitable for new energy products such as solar inverters, electric vehicle charging devices, etc., in environments with high temperature and sensitivity requirements. - Medical equipment circuit boards: serve as important components of medical equipment and meet the special requirements of high-standard medical equipment for circuit boards.