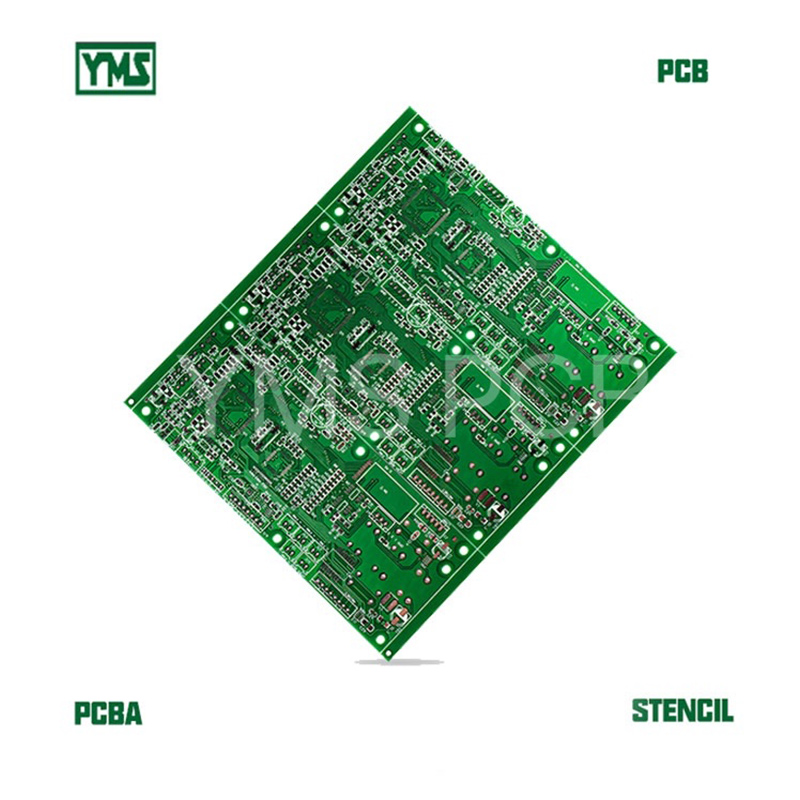

The 34-layer high-precision multi-layer printed circuit board (PCB) produced by Mingzhenghong Electronics Co., Ltd. uses back-drilling technology and laser blind hole technology to ensure circuit connectivity and signal integrity. This product uses FR-4 TG180 ITEQ (IT180A) material, with a board thickness of 5.0mm, a minimum aperture of 0.3mm, and a minimum line width and line spacing of 4mil (0.1mm). The surface treatment adopts immersion gold process (ENIG), the cutting size is 350*350mm, the outer copper layer is 35um thick, and the inner copper layer is 18um and 35um thick. It has a high aspect ratio of 17:1, and according to the IPC-III standard requirements, the inside of the hole The copper thickness should be at least 25um. The twist and warpage ratio of this circuit board is controlled within 0.5%, which is far lower than the 0.75% requirement of the IPC-II standard. The product is specially designed for semiconductor test equipment, which requires high-precision control of the lamination process, and repair of circuits and solder masks is strictly prohibited. Strict quality control is implemented for the entire board to ensure reliable use by customers in high-performance electronic testing environments.

1. Use advanced back drilling and laser blind hole technology to achieve high-precision circuit connectivity and ensure complete signal transmission. 2. Use high-quality FR-4 TG180 ITEQ (IT180A) material, the board thickness can reach 5.0mm, to meet the needs of complex circuit design. 3. The minimum aperture is 0.3mm, and the minimum line width/line spacing is 4mil (0.1mm), which is suitable for high-density circuit layout. 4. Immersion gold process (ENIG) surface treatment provides excellent conductivity and good anti-oxidation properties. 5. Strictly control the distortion and warping ratio below 0.5%, which is better than the IPC-II standard to ensure assembly and use stability.

1. The demand for circuit boards in semiconductor testing equipment, providing a stable, high-performance electronic testing environment. 2. Applications in industrial automation and medical equipment with high-precision control requirements to ensure accurate operation of the equipment. 3. High-density electronic integrated systems, such as communication equipment and 5G network base stations, require meticulous circuit design. 4. New energy products, including solar inverters and electric vehicle electronic control units, require highly reliable PCBs. 5. High-end consumer electronics, such as advanced computer systems and large servers, require high-precision multi-layer PCBs.