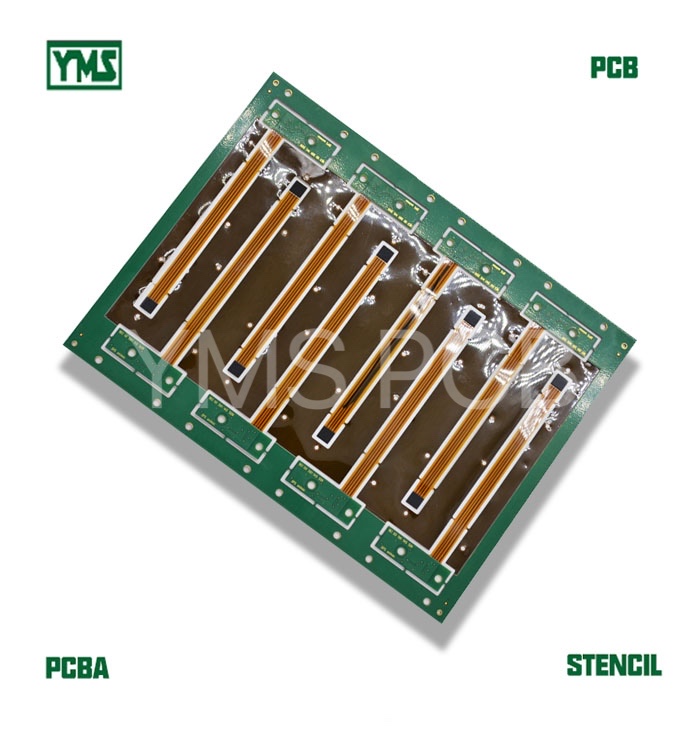

The four-layer soft-hard board provided by Mingzhenghong Electronics combines the characteristics of soft boards and hard boards and is suitable for applications requiring high flexibility. The surface treatment adopts OSP (organic anti-rust film) + ENIG (electrodeposited nickel/immersion gold), which ensures weldability while increasing conductivity and corrosion resistance. The product is specially designed with 2OZ copper thickness, which is suitable for high-power environments. At the same time, the special stacking design can meet the needs of different impedance values. Four-layer rigid-flex boards are widely used in power supplies, 5G CPE equipment, antennas and other fields. Through precision design and manufacturing, Mingzhenghong provides customers with highly reliable and high-performance PCB solutions.

- Highly integrated and flexible, integrating the flexibility of soft boards and the stability of hard boards, adapting to various complex installation environments. - Precision manufacturing, the plate thickness tolerance is controlled at 1.2mm±0.12mm, the flexible area reaches 0.15mm±0.03mm, and it supports high-density wiring and micro-aperture processing of 0.15mm. - Outstanding surface treatment technology, the OSP+ENIG combination not only ensures welding quality, but also improves the corrosion resistance and conductivity of the product. - Enhanced power tolerance, 2OZ copper thickness design is suitable for dealing with high-power environments, ensuring long-term stable operation of the product. - Customized impedance matching, special stacking design can meet specific impedance requirements and ensure signal integrity.

- Power module manufacturing, especially electronic equipment that requires high power transmission and temperature resistance. - 5G CPE equipment in the communications industry meets the requirements for high-frequency and high-speed transmission in 5G communications and ensures signal stability. - Antennas and RF modules are suitable for areas with special requirements on electrical performance and space layout. - Wearable devices and smart electronic products require high PCB bending performance and reliability. - Medical equipment and automotive electronics require high-precision applications that combine rigid impedance control and flexible wiring design.